Ainus vahe perforaator pingil on see, et perforaator pinki kasutatakse peamiselt väiksemate diameetrite puurimisel, kaasaarvatud isevoolsete torude puurimisel, kus laserkiirega juhtimissüsteemi abil suudetakse saavutada suurim täpsus hülsi või kohe paigaldatava toru puurimisel.

Suuremal augerpingil puudub aga juhtimissüsteem ja puuritakse suuremaid diameetreid. Augerpuurimise ideaaltingimuseks on pehme pinnas, kus puuritavad pikkused ulatuvad juba kuni 120 meetrini (olenevalt pinnasest) ning on võimalik paigaldada ja renoveerida ka isevoolseid torustikke.

• Ettevalmistatud hülss ühendatakse tõukemasinaga

• Peale esimese hülsi puurimist tõmmatakse masin raamil tagasi ja lisatakse uus toru ning tigukonveierid ühendatakse üksteisega

• Ekskavaator ja/või kaevamiseks ja tõstmiseks

• Alguskaevikusse paigaldatakse tellija poolt antud kõrgusele ja kaldele tugiraam ja masin

• Tigukonveier asetatakse hülssi

• Ettevalmistatud hülss ühendatakse tõukemasinaga

• Peale esimese hülsi puurimist tõmmatakse masin raamil tagasi ja lisatakse uus toru ning tigukonveierid ühendatakse üksteisega

• Peale puurimise lõpetamist tõmmatakse kõik tigukonveierid torust välja alguskaevikusse ja avatakse ükshaaval

• Ühendatakse lahti puurpea

• Ülejäänud masinad tõestetakse august välja

• Puhastatakse hülss

• Töö on valmis ja hülssi on võimalik soovitud torustik paigaldada.

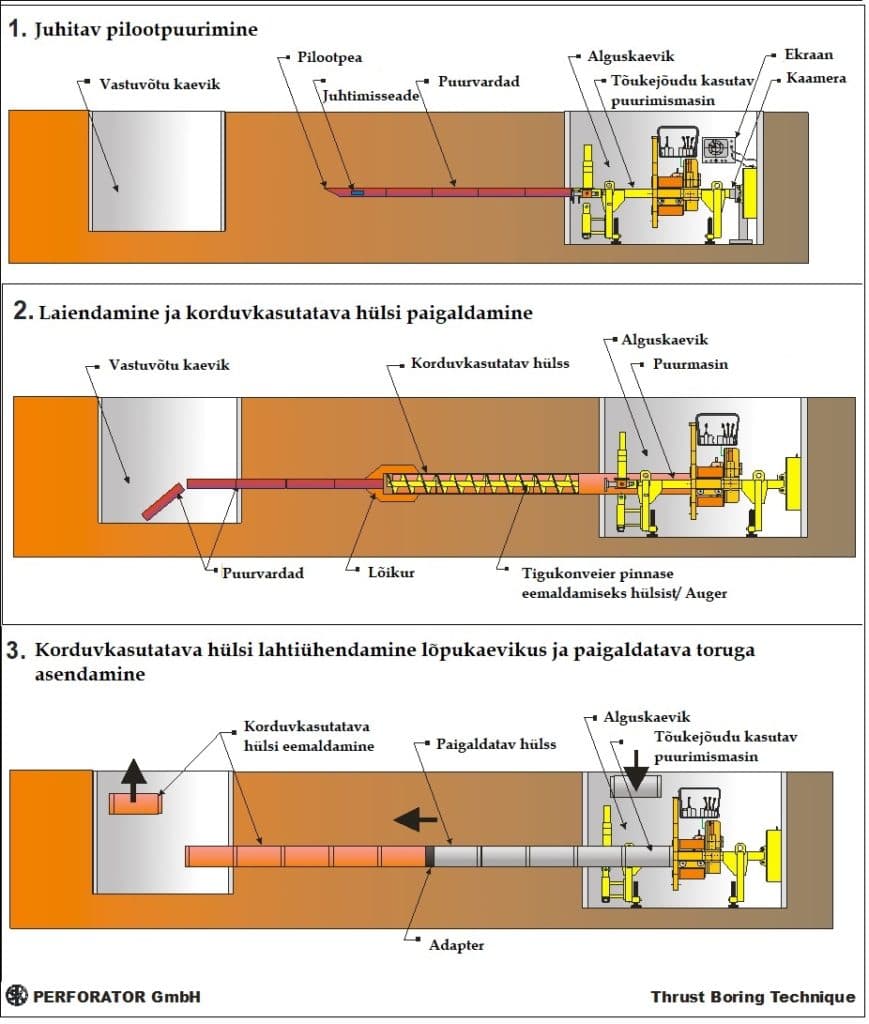

Tehnoloogiselt kokku võttes pressitakse augerpuurimisel kaevikus oleva raami abil toru pinnasesse. Seal ees olev puur peab olema vastavuses paigaldatava hülss toru diameetriga (et kivid ei satuks puuri ja puuritava toru vahele ega ummistaks tigukonveierit ning et ei tekiks pinnasevajumist). Samuti, et toru sees olev tigukonveier eemaldaks puurimisest tulevaid pinnase jääke välja.

Enne puurimise alustamist seadistatakse paika puurimise suund ja kalle, sest puurimise ajal ei saa seadet enam suunata nagu seda on võimalik teha suundpuurimisel. Peale toru paigaldamist eemaldatakse puurpea ja torus oleva tigukonveieri tagasitõmbamisel puhastab toru pinnasest ning hülssi paigaldatakse soovitud torustik.

Oleme Eesti üks suurimaid horisontaalpuurimise ettevõtteid, kelle põhitegevuseks on surve-, vee-, kaabli- ja kanalisatsioonitrasside (ka isevoolsed) puurimine.

Reg nr: 12249609

KMKR nr: EE101523541